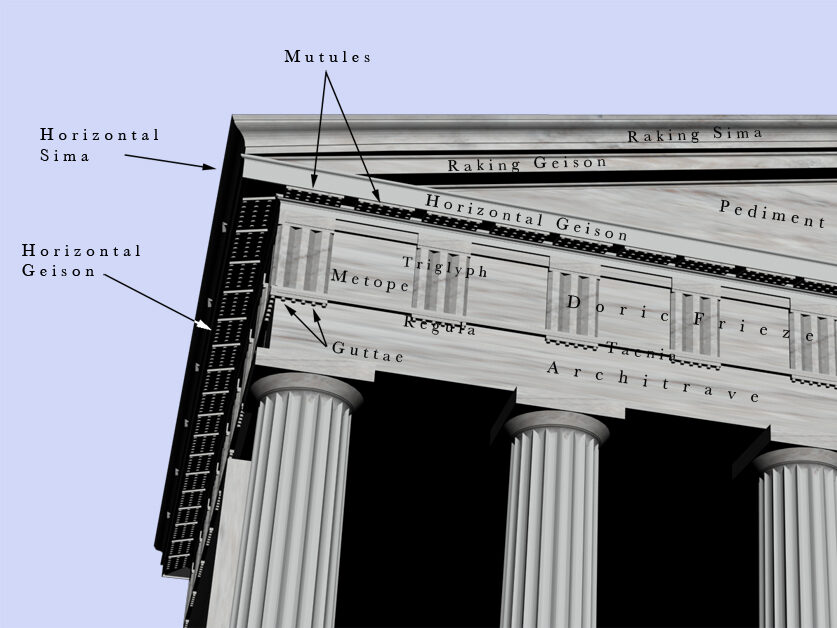

When the ancient Greeks erected their first temples from stone, they incorporated construction features found in earlier temples made of wood. Wooden columns, supporting wooden beams (architrave), and even the end of the joists (triglyphs) showed the binding pegs underneath (guttae), yet these guttae served no structural purpose. Presumably, this was so the new stone temples retained the essential appearance of what the populous expected a temple to look like. This was stone imitating wood.

At the time the first bridge to be made of cast iron was contemplated, bridges had been made of both stone and wood for millennia. The Romans famously constructed a massive bridge across the Danube (1.2 km long, 19 m high and 15m wide), a wooden structure on stout stone and mortar, brick faced piers 50 m apart. These piers lasted the centuries and had to be blown up in the 20th century to allow river navigation. Yet when constructing a bridge from cast-iron, there was no experience in how one might join the component parts. Iron had many of the features of wood but with much higher carrying capacity, so the iron workers turned to wooden joinery techniques and applied them to iron. The iron members were joined with mortice and tenon joints, then secured with dowels and pegs, also made of iron.

The first cast iron bridge was opened for toll across the River Severn near Telford in Shropshire in 1781. Large scale iron work had become possible in Britain after the discovery that coal could be turned into coke by driving off the volatile components in a hot oxygen poor atmosphere. This innovation had allowed much larger volumes of iron to be produced than ever before. Previously, charcoal derived from wood was used which could only support the smelting of a small amount of iron ore. The furnace pile of ore on charcoal would collapse if too much ore were added. Now, with the large volumes of iron being produced, iron was quickly in need of problems to solve.

Abraham Darby III, at age 23, underwrote the construction of the cast-iron bridge in the hope that it would lead to more construction work. It was a huge gamble, and it took 12 years to return the investment, requiring additional mortgages to save the iron working business from bankruptcy. Other iron bridges had already been considered or attempted, with a wrought iron bridge completed as an ornamental walkway in 1769, but the bridge over the Severn was the first large-scale cast-iron construction. It marked a turning point in bridge construction and rang in a new iron-age.

The success demonstrated with this cast-iron bridge, led to even more ambitious projects being undertaken. Ever higher pressure steam boilers provided the power for the industrial revolution. Viaducts constructed from iron allowed canals to bridge valleys, with great success. Much later in 1871, construction began on a massive cast-iron railway bridge across the River Tay but it was here that iron’s limitations would be tragically demonstrated. In1879, during a massive storm, the bridge collapsed as a train was passing over it, killing all 75 on board. The high carbon content of cast iron, while more impervious to corrosion, makes it brittle and lowers the tensile strength. This disaster marked the end for cast-iron for large scale construction and, together with the Bessemer process for removing carbon from iron, gave rise to the age of steel. Steel, on the other hand, has a higher tensile strength and is more elastic, making it a far superior building material for bridges and skyscrapers. Yet, the use of iron in this novel way was a necessary intermediate step to pave the way for even better ways of doing things.

While cast-iron turned out not to be the best construction material, the bridge over the River Severn survives until the present day as a popular tourist destination. It was a pedestrian toll bridge until 1950. Over the centuries and indeed most recently, it has gone much restoration work, fixing cracks in the iron work, but also stabilising the embankments of the river which had been threatening to compress the bridge.

One might say that crucial to such innovation was the ironclad guarantee of property rights as laid out in Magna Carta, when it was cast in stone in 1225. Those who took the risks could rest assured that the returns would be theirs to keep, less taxes to the Government which guarantees those property rights. Yet nothing would have been possible without the application of the scientific method, generating hypotheses and then testing these against empirical data. Over time, a greater understanding of metallurgy was gained, allowing better metal alloys and smelting techniques to be developed. This, together with more advanced manufacturing techniques, has facilitated the creation of massive and breath-taking structures.